News

Are you full of unknowns about the parts of the equipment and do not understand its actual functions? Every component plays an important role and is indispensable.

Let KEENPRO introduce the small functions of the bottle blowing machine - wattmeter.

About KEENPRO

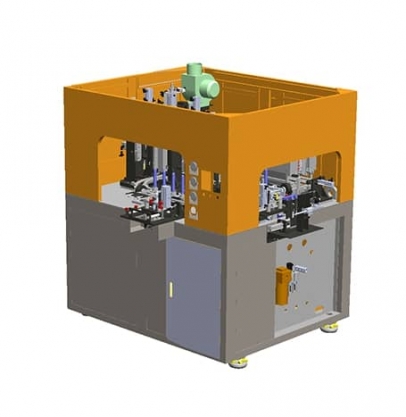

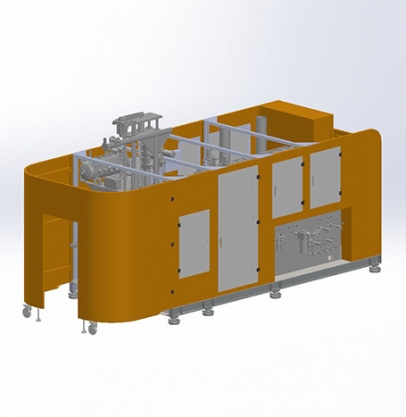

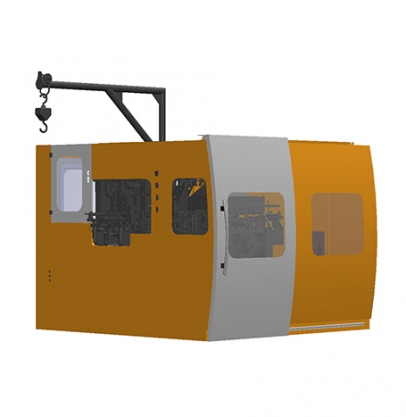

What is KEENPRO? Is KEENPRO only a machine seller? No, we are more than what you think! 「KEEN」, with enthusiasm to tackle obstacles and overcome difficulties. 「PRO」, with our experience to provide comprehensive services to our customers, committed to PET automatic blowing equipment research and development and production. Since the establishment in 2008, we have always maintained the “INNOVATIVE VALUE, DELICATE PRODUCTS, and PROMPT SERVICE” spirit, and constantly improve the stability and quality of equipment to create maximum value for customers. KEENPRO ensures delicate products, and we care about the status of the machine. Through the feedback of customers, we can develop products that had fully meet the needs. KEENPRO provides fast services. Our professional team can solve ...

-

No.221, Lane 460, Sec.1,Xinan Road,Wuri Dist., Taichung City 41462, Taiwan

-

+886-4-23345539

+886-4-23345539

- Designed by GTMC

- Taiwan Products

- B2BManufactures

- Market-Prospects