Taiwanese Green Equipment, Green Tech, Exposing in Plastpol in Poland.

Plastpol was held in Poland from 2022/05/24 ~ 05/27, despite the pandemic, it still showed the great power of economic activities preparing for the post-pandemic era. Poland links up the West Europe and the East Europe, it possesses the geographical advantage, high labour quality, rich in mineral resources, and it becomes a popular country for foreign investors, and the economy development is definitely eye-catching.

As the environment awareness increases globally, it is getting popular to prepare one’s own shopping bag to shop as well as the second-hand shops in Poland, even the products without packaging or exchanging the used products, these are becoming the common buying pattern in Poland. Citizens in Poland promote the healthy living and own strength to support the environment protection.

In recent years, the high molecular material for the close-loop applying technology has been developing actively in the rubber and plastic industry. Whether it is the new material development or improving the re-using recyclable materials, the Green Economy is today and tomorrow’s important agenda for most of the well-known enterprises’ marketing strategy. This prospect and business opportunity will attract more enterprises to invest and follow the close-loop economy as their target, and it will also become the growing force and economic recovery for the post-pandemic era.

The G.M. of KEENPRO, Mr Tom Huang has accepted the TAITRA’s interview, and has discussed and shared the Green Equipment from KEENPRO in depth. Mr Huang pointed out that, the popular PET material is very suitable for re-use and recycle, thus the rPET is one of the popular recycled materials today. PET may divides into 2 types of recycles, one is by mechanical, and chemical is another. Although the rPET contains more impurities when recycled by mechanical, but the carbon footprint shows it is better than by chemical method. The quality of the recycled resins cannot compare with the virgin resins, and the rPET preforms are slightly unstable, lower production rate and higher defect rate when blowing into bottles comparing with virgin PET preforms.

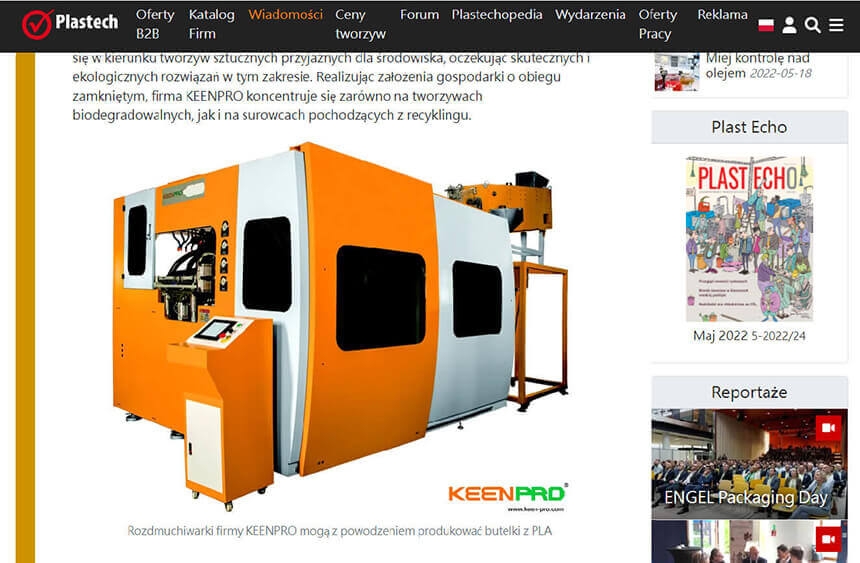

A Cambodian partner of KEENPRO’s, they have been supporting the environment awareness since very early stage, and have decided to use 50% rPET preforms to produce bottles, and they chose to use those materials which recycled by mechanical method. KEENPRO faced this difficult and stubborn rPET material for the first time, but after several tests and adjustments, KEENPRO finally has conquered the challenge, and KEENPRO’s blowing machine has successfully blown the 50% rPET bottles. Also, KEENPRO tested the 30% and 75% rPET preforms respectively. KEENPRO possesses high standard engineers and the professional skills, to provide the most appropriate problem-solving solutions to its customers globally.

Please click the link below to read more exciting articles from Taiwanese enterprises which were interviewed and posted on the Plastpol official website :

https://www.plastech.pl/wiadomosci/Maszyny-z-Tajwanu-dla-zielonej-gospodarki-17707

Welcome to go and support them.

Perhaps we need to give more when we “go Green”, but this is such a godsend for all the living being on Earth. Listening and Solving your problem is KEENPRO’s Mission, and it is the Value for KEENPRO’s existence.