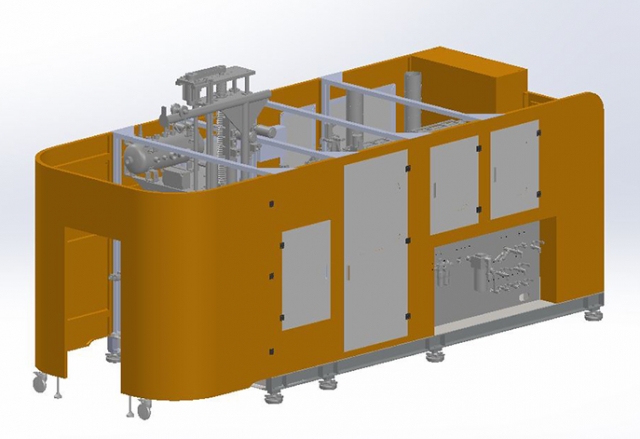

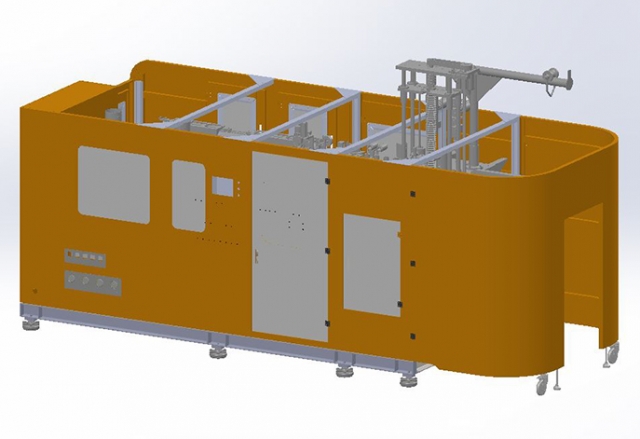

BLOW MOLDING MACHINE (LM02L)

LM series blowing machine is suitable for bigger volume PET bottles, it can easily tackle the thick, heavy, long preforms, up to 12L of bottle volume. It comes with quick-changing mold design, so it reduces more time, energy and user-friendly during mold changing.

| Model | LM02L |

|---|---|

| Maximum capacity (ml) | 12000 |

| Theoretical capacity (BPH) | 2000 |

| Maximum bottle size (mm) | Ø210*H450 |

| Preform tooth mouth (mm) | Ø18-Ø50 |

| Filling temperature (°C) | <49︱50-69 |

Additional files

LM02L.pdfFeatures

Infeed

- It uses precision star-wheel to send the preforms into the transfer system.

Transfer

- Uses servo motor, in order to have precise positioning.

- Preforms move horizontally, no need to flip.

- Short heating pitch, less energy needed and with high efficiency.

- Variable lead uses cylinder to operate and servo to track, ensures to operate stably.

Heating

- Uses continuous collective heating method.

- Neck hangs at top, preform will not be deformed after heating.

- Lamps controlled by SCR, ensures the preforms heated evenly.

- Side opening design on the heating box, increase the convenience for maintenance.

- Water ducts and blowing device, avoiding the preform necks get swollen.

Forming

- Clamping mechanism uses servo motor with cam drive.

- Heated preforms through variable lead, and then enter into the mold by using grippers

- Mold is placed near to the side of the machine, with quick-changing design, easy to operate, saving time and energy.

Blowing

- High pressure air is recovered to the storage tank, and then re-used on low pressure systems where needed.

- Air-recovery rate up to 45%, we obtained the German patent for this core technology.

- KEENPRO’s patented high pressure valve, it even attracted some valve suppliers to buy from KEENPRO.

Operation

- HMI with colourful touch screen, easy to operate.