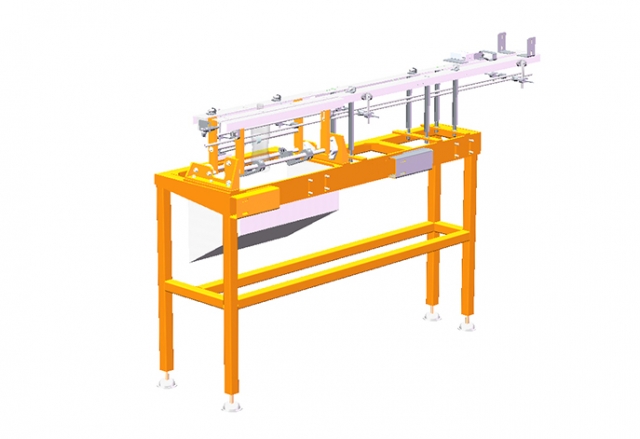

Swing-Arm Conveyor

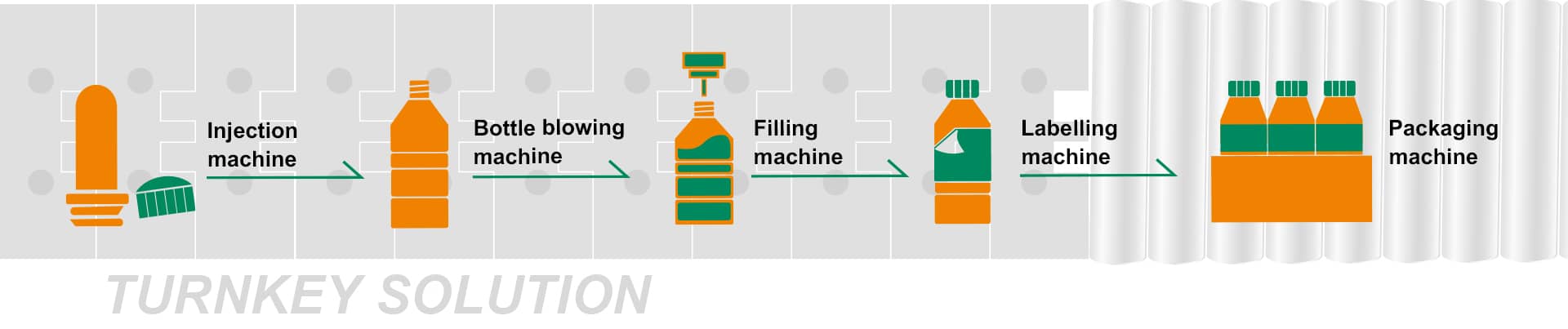

There are plenty bottle designs on the market, but the production process may be very different. From the bottle production methods: extrusion, injection-blow, injection stretch-blow (one-stage or two-stage), to the entering into the conveyor belt before the filling, there are some distinctive differences.

How a customer should choose his/her Conveyor Belt?

1. KEENPRO will give the suggestion according to the bottle design & shape. The bottle with CSD bottle base, we will suggest to use Swinging Arm Conveyor Belt. Because the surface of the CSD bottle base is smaller, and it is easy to tip, thus using the Swinging Arm Conveyor Belt will be better than the Top Chain Conveyor.

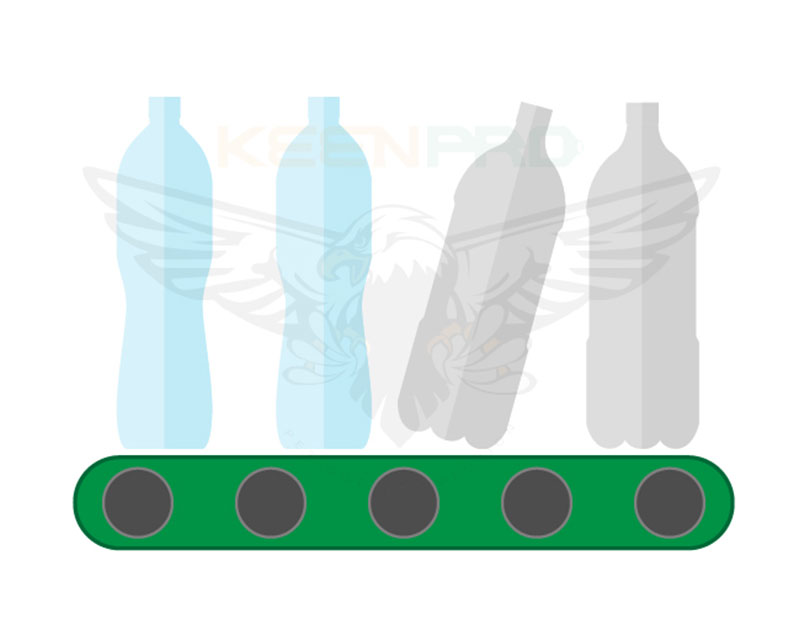

Like the Drawing above, the CSD bottle base is easy to tip.

2. For the lighter weight bottles, we suggest to use Swinging Arm Conveyor Belt. Because when the lighter bottles reach on the Conveyor Belt will bounce slightly, and then cause to tip over.

3. For the rest of the bottle designs, customer may choose either Top Chain or Swinging Arm Conveyor Belt according to their preference.

Listening to and solving your problem is KEENPRO’s Mission and the Value of KEENPRO’s existence. Customers' satisfaction is what KEENPRO cares about, from the equipment to small details, KEENRPO will not tolerate any imprudent mistakes, because we want to provide the perfect service.