KEENPRO 8-Cavity EM Energy-saving Bottle Blowing Machine For Large Fish Sauce Factory In Myanmar

KEENPRO has always been harmonious with upstream and downstream manufacturers. Two years ago, the upstream manufacturer introduced that we actively approached the large fish sauce company that has been operating in Myanmar for more than 20 years. The company’s fish sauce products have 60% of the local market rate.

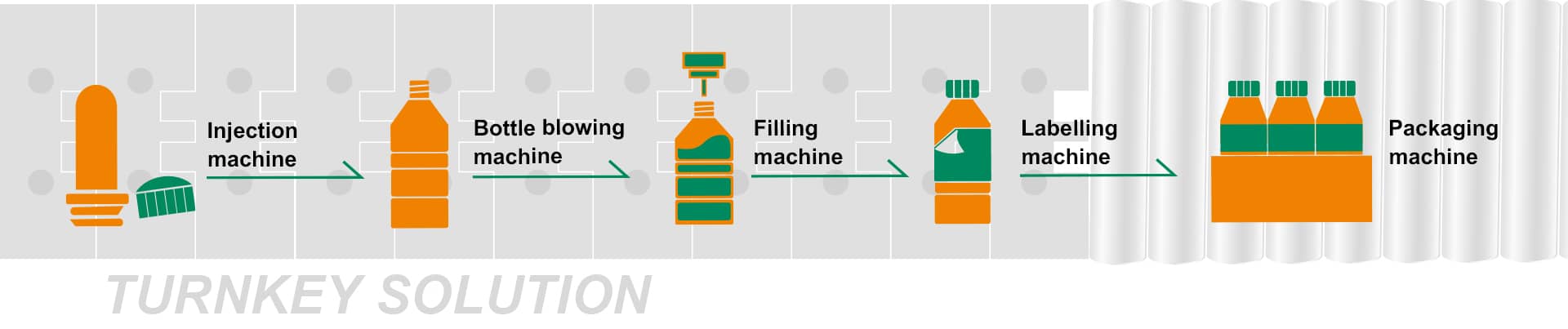

KEENPRO explores the needs of customers in-depth, plans suitable solutions for him, analyzes and explains, and facilitates customers to make decisions. Because customer products need to be able to supply to Myanmar promptly, products have to produce continuously for a long time. Therefore, the durability and power consumption of the machine is given priority consideration by customers. In the follow-up, the power consumption of the machine is verified through power measurement.

Based on the SGS power measurement results, the KEENPRO blow molding machine can save up to 60% of the electricity consumption, which proves that the KEENPRO EM energy-saving blow molding machine is more efficient than other brands of equipment. Power saving allows customers to carry out long-term production planning more effectively. Besides, air compressors also use high-efficiency models, which have higher compression efficiency, generate more air volume, and save more electricity. Finally, the customer chose us to introduce KEENPRO EM08S2-88 8 cavity blow molding machine.

During the period of use, the customer showed the other party's satisfaction in terms of use and service to KEENPRO and hoped to have more cooperation plans in the future. It is an infinite honor for us to obtain the affirmation and trust of our customers, which also gives us more confidence to fight for future cooperation orders.

If you are interested in EM energy-saving blow molding machine, please click the link, or contact us directly: