Dairy product upgrade [only melts in your mouth, does not scratch your hands]

After years of planning and preparation, the leading dairy product brand will successively carry out major material conversion projects for its various dairy product bottles and cans starting from 2022. Under the fierce competition of information transparency in the digital age, KEENPRO uses professionalism and enthusiasm to conduct rigorous inspections. Stand out from the comparison and become the leading manufacturer of material conversion.

The leading dairy brand upgrades the image of dairy products, taking off the rough and scratchy white shell HDPE bottle, and putting on a light, smooth and comfortable PET bottle, [only melts in your mouth, does not scratch your hand] makes opening the bottle and drinking more wanton and enjoyable Peace of mind, provide consumers with a comfortable drinking taste, and feel in love with the drink from the moment they touch the soft lips. From the perspective of consumers, the change of material provides comfort and peace of mind. From the perspective of enterprises, it not only saves costs, but more importantly, it has the deep meaning of social responsibility and caring for the earth.

PET has excellent tensile toughness, so less material is used, and the weight of the bottle is naturally reduced. The cost from material use to delivery is relatively low, and the cost reduction is achieved through the characteristics of the PET manufacturing process. From the perspective of carbon footprint, plastic is actually very environmentally friendly! ! Carbon footprint not only refers to the carbon emissions emitted during production and manufacturing, but also includes the carbon emissions of transportation, consumption, recycling and other overall links. The energy consumption of plastic manufacturing is much lower than that of other cloth products, paper products, metal and even glass products. Coupled with the advantages of light weight, drop resistance and durability, it is also among the best in transportation. The 100% recyclable PET material is the icing on the cake. *NAN YA said that by recycling technology, compared with traditional petrochemical processes, carbon emissions can be reduced by about 72%. And now there are technologies and examination certifications for the recycling and remanufacturing of food-use PET as raw materials for food utensils, containers, and packaging. The US FDA and the European Union EFSA have relevant certifications. The Taiwan Food and Drug Administration of the Ministry of Health and Welfare also announced relevant application process. * The sustainable solution for environmental protection is reusability, which is also the deep meaning of leading dairy brands in material conversion.

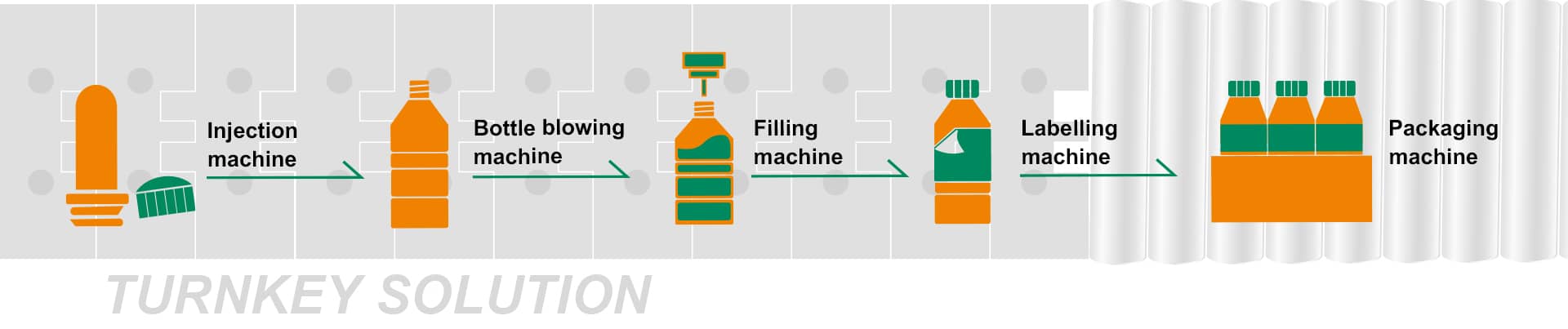

The leading dairy brand chooses KEENPRO’s customized energy-saving equipment with international certification to pioneer the conversion of materials. KEENPRO provides stable, high-quality and energy-saving bottle blowing equipment, and joins hands with the leading dairy brand to contribute to the earth. Listening to and solving your problems is our mission, and it is also the value of KEENPRO 's existence. Your trust will stimulate our creativity and innovation. If you are interested in material conversion, please click the link, or contact us directly: https://reurl.cc/qO8kEg.

*Citation source:

Finance.com News NAN YA promotes recycling of plastic bottles with supermarket channels to implement sustainable development"