THE INDISPENSABLE AUXILIARY EQUIPMENT IN THE PET BOTTLE PRODUCTION

You can see bottled water, juice, and beverages everywhere, and they have become the most trusted, most convenient, and most popular choice.

To take into account the quality of the PET bottle production process, they have to go through multiple strict inspections. Ifused with auxiliary equipment, it can not only greatly increase production capacity and work efficiency, but also reduce personnel costs, and bring many actual benefits.

The secret hero of PET bottles:

- Dumper: Pour a large number of preforms into the storage bucket,successfully shortening the operation process. To improve the safety of the equipment, KEENPRO added a safety door sensor to ensure that the machine can only start the power supply and resume operation when people leave the area.

- Compressor: It provides compressed air for the blowing process with high efficiency, high reliability, and high stability. It is special equipment for the PET bottle blowing industry.

- Chiller: To keep the shape of the preform neck not deformed and easy to peel off, it is necessary to drop the mold temperature through the Chiller.

- Cooling tower: To cool down the air compressor and chiller, it needs the assistance of a cooling tower.

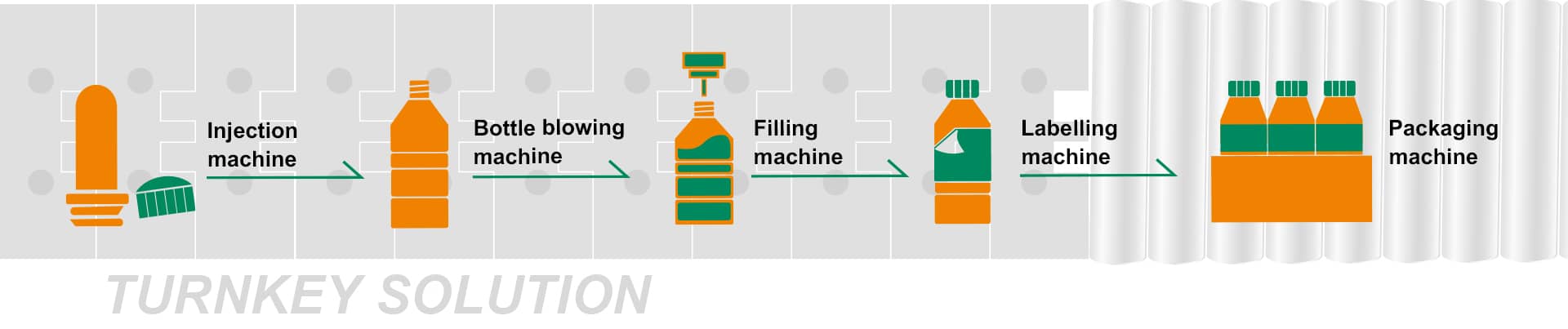

KEENPRO is the leading brand of PET bottle blowing, upholding to create maximum value for customers, constantly looking for the most suitable solutions for users, and providing the most suitable turnkey.

It is our mission to listen to and solve your problems, and it is the value of KEENPRO!