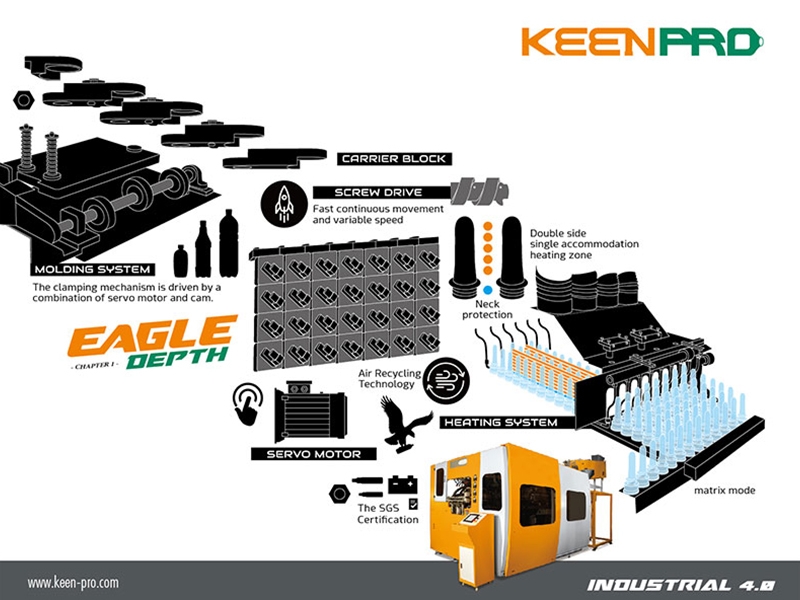

KEENPRO PUSHING THE BOTTLE BLOWING MACHINE BRAND TO INDUSTRY 4.0

KEENPRO is committed to the manufacture and design of PET Stretch Blow Molding Machines and devoted to research and development for decades. We have breakthrough performances for energy saving, environmental protection, high production capacity, lightweight trend, and Intelligent system.

The company spirit of KEENPRO is like an eagle flying in the vast sky. In addition to understanding market trends and expanding production to the world, it is also enhancing customer value.

KEENPRO always insists on R&D and production. To save production costs, reduce energy consumption and resources, it has finally successfully developed equipment that leads the field of blow molding machines into Industry 4.0:

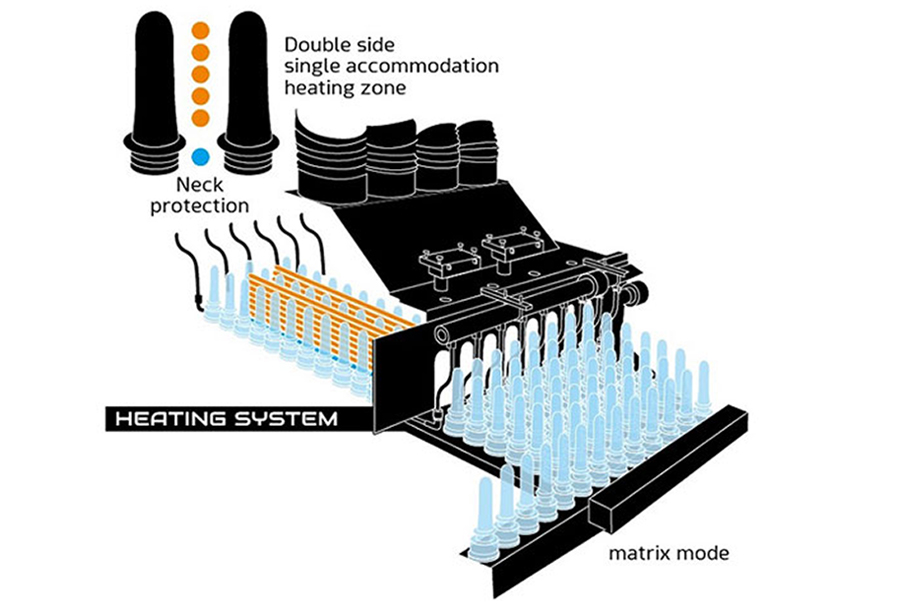

1. Heating system:

- The preforms feed into the heating system ina parallel horizontal matrix mode.

- Single-lamp bilateral heating technology make preforms eventually heat.

▲Heating system

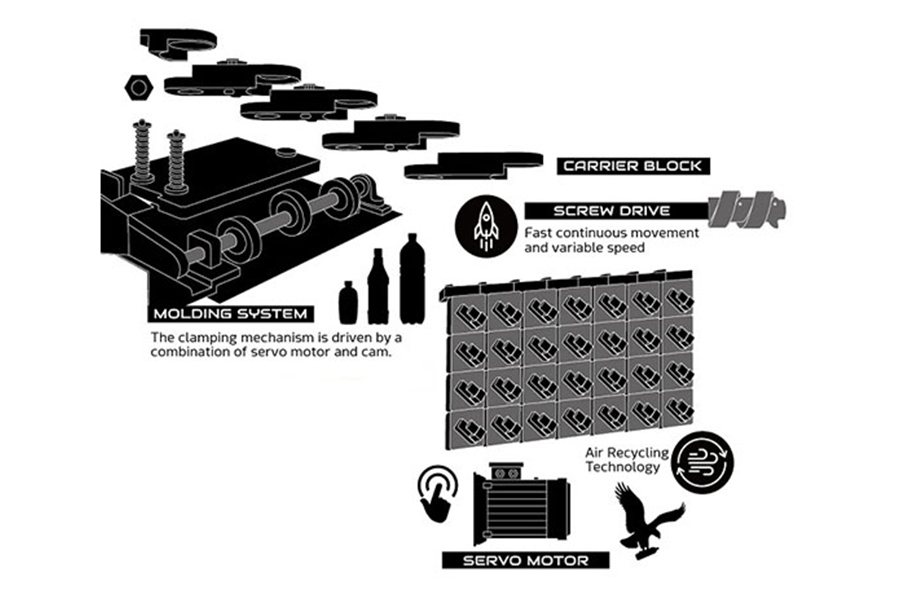

2. Molding system:

- The parallel valve design and gas recovery system can reduce energy consumption and increase recovery efficiency.

- The clamping mechanism is driven by a combination of servo motor and cam.

3. Transfer system:

- Screw driven controlled by servo motor providing fast and smooth motion.

▲Molding system & Transfer system

KEENPRO adopts microcontrollers (MCU) for the establishment and integration of various intelligent systems. Also, successfully pushed the blowing machines to Industry 4.0 through network communication, data acquisition, and machine control.